Circuit breakers are indispensable devices in electrical systems, serving as crucial safety measures that protect circuits from damage caused by excessive current. As technology advances, many circuit breakers have emerged to cater to specific requirements and applications. In this comprehensive guide, we will explore 50 different types of circuit breakers, highlighting their unique characteristics, advantages, disadvantages, and practical uses. Let’s embark on this illuminating journey into the world of circuit breakers.

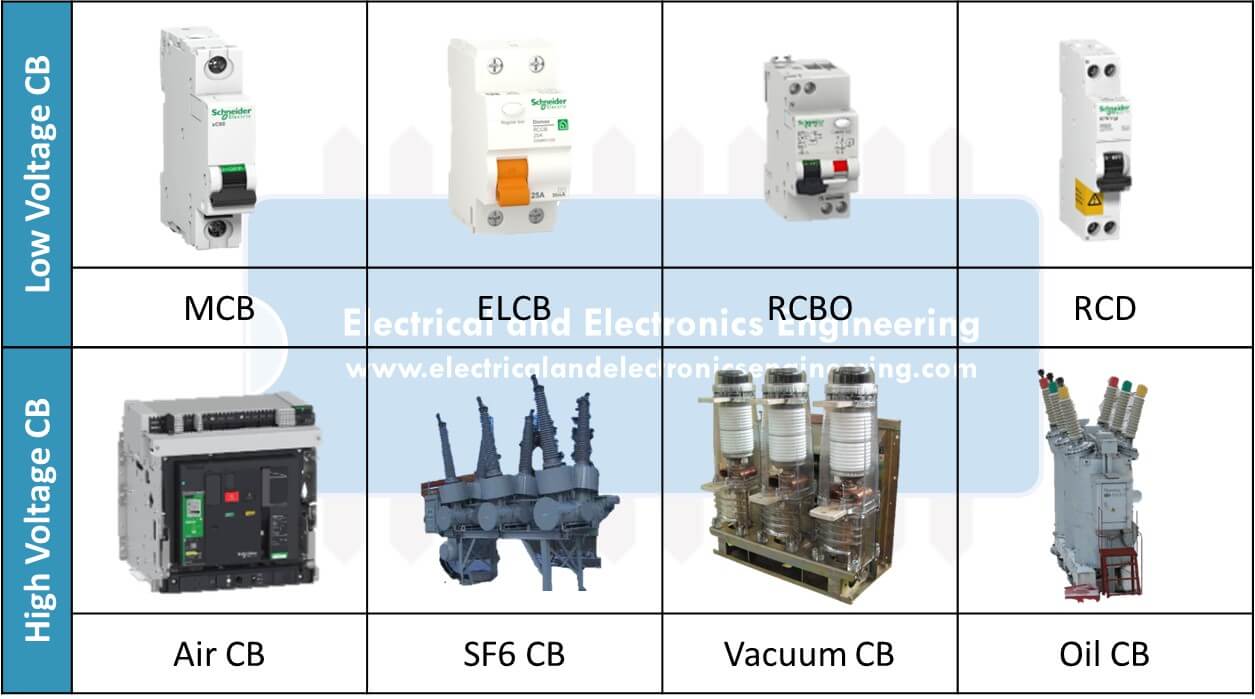

Low Voltage AC Circuit Breakers

Miniature Circuit Breaker (MCB)

A Miniature Circuit Breaker, commonly known as an MCB, is a compact circuit breaker designed for low-voltage applications. It protects against overcurrent and short circuits in residential, commercial, and light industrial settings. MCBs are widely used due to their compact size, ease of installation, and quick response to electrical faults.

Advantages of MCB

- Compact size allows for installation in limited space

- Provides reliable protection against overcurrent and short circuits

- Quick response to electrical faults, minimizing damage and downtime

- Easy to reset after tripping

- Cost-effective solution for low-voltage applications

Disadvantages of MCB

- Limited capacity for high-power applications

- May not provide adequate protection against specific electrical faults, such as earth leakage

Practical Applications of MCB

- Residential buildings

- Small commercial establishments

- Light industrial settings

Molded Case Circuit Breaker (MCCB)

A Molded Case Circuit Breaker, or MCCB, is a type of circuit breaker widely used in commercial and industrial applications. It offers higher current ratings compared to Miniature Circuit Breakers and provides reliable protection against overcurrent and short circuits. MCCBs are known for their robust construction and durability.

Advantages of MCCB

- Higher current ratings suitable for industrial applications.

- Robust construction ensures durability in demanding environments.

- Provides reliable protection against overcurrent and short circuits.

- Easy to install and maintain.

Disadvantages of MCCB

- Larger in size compared to MCBs.

- Higher cost compared to MCBs.

Practical Applications of MCCB

- Commercial buildings.

- Industrial facilities.

- Large-scale power distribution systems.

Earth Leakage Circuit Breaker (ELCB):

An Earth Leakage Circuit Breaker, or ELCB, is a specialized circuit breaker designed to detect and protect against electrical leakage currents. It is primarily used to prevent electric shock and fire hazards caused by faulty grounding or insulation in electrical systems.

Advantages of ELCB

- Detects and protects against electrical leakage currents, ensuring safety.

- Automatically trips when leakage currents exceed a predetermined threshold.

- Provides additional protection against electric shock and fire hazards.

Disadvantages of ELCB

- May not provide adequate protection against overcurrent or short circuits.

- Requires proper installation and periodic testing.

Practical Applications of ELCB

- Residential buildings.

- Commercial establishments with sensitive electrical equipment.

- Locations where electrical leakage poses a risk, such as swimming pools or wet environments.

Voltage ELCB

A Voltage Earth Leakage Circuit Breaker, or Voltage ELCB, is a type of ELCB that detects electrical leakage by comparing the incoming and outgoing voltages in a circuit. It is designed to protect against insulation faults, such as accidental contact with live parts or deterioration of insulation.

Advantages of Voltage ELCB

- Provides reliable protection against insulation faults.

- Automatically trips when voltage imbalances exceed a predetermined threshold.

- Offers additional protection against electric shock and fire hazards.

Disadvantages of Voltage ELCB

- Limited in detecting certain types of electrical faults, such as overcurrent or short circuits.

- Requires proper installation and periodic testing.

Practical Applications of Voltage ELCB

- Residential buildings.

- Commercial establishments with critical electrical equipment.

- Locations with a high risk of insulation faults, such as hospitals or data centers.

Current ELCB (RCCB)

A Current Earth Leakage Circuit Breaker, or RCCB, is another type of ELCB that detects electrical leakage by monitoring the current imbalance between the live and neutral conductors in a circuit. It is widely used to protect against electric shock and fire hazards caused by electrical leakage.

Advantages of Current ELCB

- Detects and protects against electrical leakage currents, ensuring safety.

- Automatically trips when current imbalances exceed a predetermined threshold.

- Provides additional protection against electric shock and fire hazards.

Disadvantages of Current ELCB

- May not provide adequate protection against overcurrent or short circuits.

- Requires proper installation and periodic testing.

Practical Applications of Current ELCB

- Residential buildings.

- Commercial establishments with sensitive electrical equipment.

- Locations where electrical leakage poses a risk, such as kitchens or bathrooms.

Residual Current Breaker with Overcurrent (RCBO)

A Residual Current Breaker with Overcurrent, or RCBO, combines the functionalities of a residual current device (RCD) and a circuit breaker. It offers protection against electrical leakage currents, overcurrents, and short circuits, making it a versatile safety device for various applications.

Advantages of RCBO

- Provides combined protection against electrical leakage, overcurrents, and short circuits.

- Automatically trips when current imbalances or overcurrents exceed predetermined thresholds.

- Offers comprehensive electrical safety.

Disadvantages of RCBO

- Higher cost compared to individual circuit breakers or RCDs.

- Requires proper installation and periodic testing.

Practical Applications of RCBO

- Residential buildings.

- Commercial establishments with critical electrical equipment.

- Locations where comprehensive electrical protection is essential, such as hospitals or industrial facilities.

- By covering a range of circuit breakers, from MCBs to RCBOs, we can ensure the safety and reliable operation of electrical systems in various settings.

RCB – RCD or RCCB

The term RCB is a generic terms. RCB stands for Residual current breaker and it encompasses two components: the RCD (Residual Current Device) and the RCCB (Residual Current Circuit Breaker). An RCD serves the purpose of swiftly disconnecting the circuit whenever a residual current surpasses a specified threshold. Residual current, in this context, signifies an imbalance of current between the live and neutral conductors.

Classification of Circuit Breakers on basis of Curve

Miniature Circuit Breakers (MCBs) play a critical role in safeguarding electrical circuits by providing overcurrent protection. They are available in various types, each designed to cater to specific applications and load characteristics. In this article, we will explore different types of MCBs and their practical uses.

Type A Miniature Circuit Breakers

Type A MCBs are specifically designed for low levels of overcurrent protection. They are primarily used to protect highly sensitive devices, such as electronic equipment and appliances that require precise and delicate operation.

Type B Miniature Circuit Breakers

Type B MCBs trip when the current exceeds 3 to 5 times the rated current, with an operating time ranging from 0.04 to 13 seconds. They are ideal for resistive loads and non-inductive loads, or loads with minimal inductance. Type B MCBs find common applications in low-power domestic settings like lighting circuits and home wiring systems.

Type C Miniature Circuit Breakers

Type C MCBs are designed to handle current values ranging from 5 to 10 times the rated current, with an operating time of 0.04 to 5 seconds. They are specifically suitable for use with inductive loads, including motors, fans, and transformers, where sudden current rushes or surges can occur. These MCBs are commonly found in commercial and industrial applications.

Type D Miniature Circuit Breakers

Type D MCBs are characterized by a trip current of 10 to 20 times the rated current, with an operating time of 0.04 to 3 seconds. They are specifically designed for high inductive loads. Type D MCBs are primarily used in high-power industrial applications, providing protection for heavy-duty equipment such as motors, transformers, x-ray machines, and welding devices.

Type K Miniature Circuit Breakers

Type K MCBs trip when the current reaches 8 to 12 times the rated current, with an operating time of less than 0.1 second. These MCBs are well-suited for circuits with inductive loads that may experience high inrush currents, such as motor circuits.

Type Z Miniature Circuit Breakers

Type Z MCBs operate at current values between 2 to 3 times the rated current, with an operating time of less than 0.1 second. These MCBs, often referred to as Class Z MCBs, are specifically designed to protect semiconductor devices and are commonly utilized in electronic circuits.

By understanding the various types of MCBs available, electrical professionals can select the most suitable option for their specific applications. It is crucial to consider the nature of the load, the potential for current fluctuations, and the required response time when choosing the appropriate type of MCB.

High Voltage AC Circuit Breakers

Air Circuit Breaker (ACB)

An Air Circuit Breaker (ACB) is a type of circuit breaker that uses air as the arc quenching medium. It is commonly used in low voltage applications and offers reliable protection against overcurrent and short circuits. ACBs consist of a set of contacts that open and close to interrupt the circuit when necessary. The ACB is often used as an electrical device designed to provide short circuit and overcurrent protection ranging between 800 amperes to 10K amperes to connected devices.

Advantages of ACB

- Wide range of current ratings and breaking capacities.

- Fast response time for effective protection.

- Easy maintenance and inspection due to the simplicity of design.

- Suitable for high fault currents.

- Can be easily retrofitted in existing electrical systems.

Disadvantages of ACB

- Larger in size compared to other types of circuit breakers.

- Higher cost compared to some alternative technologies.

- Air-based arc extinguishing medium may have limitations in handling high-energy arcs.

Practical Applications of ACB

- Industrial and commercial buildings.

- Power distribution panels.

- Generator protection systems.

Sulphur Hexafluoride (SF6) Circuit Breaker

SF6 circuit breakers utilize sulphur hexafluoride gas as the arc quenching medium. They are commonly used in high-voltage applications, where they provide excellent performance and reliability.

Advantages of SF6 Circuit Breaker

- High dielectric strength allows for compact design.

- Excellent arc quenching properties.

- Minimal maintenance requirements.

- Suitable for high-power applications.

- Long service life.

Disadvantages of SF6 Circuit Breaker

- SF6 gas has a high global warming potential.

- More complex maintenance requirements.

- Higher cost compared to some alternative technologies.

Practical Applications of SF6 Circuit Breaker

- High-voltage power transmission and distribution networks.

- Industries with high-power demand.

- Electrical substations.

Vacuum Circuit Breaker (VCB)

Vacuum circuit breakers utilize a vacuum as the arc quenching medium. They have gained popularity due to their compact size, reliable operation, and minimal maintenance requirements.

Advantages of VCB

- Compact design, ideal for space-constrained applications.

- Low maintenance requirements.

- Environmentally friendly (no greenhouse gas emissions).

- High breaking capacity.

- Fast and reliable operation.

Disadvantages of VCB

- Limited current interrupting capacity compared to some other technologies.

- Higher cost compared to air circuit breakers.

· Practical Applications of VCB

- Industrial and commercial buildings.

- Electrical panels and distribution boards.

Power distribution systems.

Bulk Oil Circuit Breaker (BOCB)

A Bulk Oil Circuit Breaker (BOCB) is an older type of circuit breaker that uses a large quantity of oil as the arc extinguishing medium. It consists of an arc chute immersed in oil, which provides effective cooling and extinguishing properties.

Advantages of BOCB

- Excellent arc quenching capability.

- Suitable for high-voltage applications.

- Relatively simple design.

Disadvantages of BOCB

- Environmental concerns related to oil leakage.

- High maintenance requirements.

- Large size and higher cost compared to newer technologies.

Practical Applications of BOCB

- Older power systems and substations.

Minimum Oil Circuit Breaker (MOCB)

A Minimum Oil Circuit Breaker (MOCB) is a type of oil circuit breaker that uses a reduced amount of oil compared to bulk oil circuit breakers. This design minimizes environmental concerns associated with oil leakage and maintenance.

Advantages of MOCB

- Lower oil volume reduces environmental impact.

- Suitable for high-voltage applications.

- Relatively simple design.

Disadvantages of MOCB

- Higher maintenance requirements compared to newer technologies.

- Larger size and higher cost compared to some alternative technologies.

Practical Applications of MOCB

- Older power systems and substations.

Oil Impulse Circuit Breaker

Oil impulse circuit breakers utilize oil and a compressed air system to extinguish arcs. They offer improved performance compared to traditional oil circuit breakers by enhancing arc quenching capabilities.

Advantages of Oil Impulse Circuit Breaker

- Enhanced arc quenching properties.

- Suitable for high-voltage applications.

- Relatively simple design.

Disadvantages Oil Impulse Circuit Breaker

- Maintenance requirements associated with oil and compressed air systems.

- Environmental concerns related to oil leakage.

- Larger size and higher cost compared to newer technologies.

Practical Applications Oil Impulse Circuit Breaker

- Older power systems and substations.

DC Circuit Breakers

DC circuit breakers are specifically designed to protect direct current (DC) electrical systems from overcurrent, short circuits, and other electrical faults. Unlike AC circuit breakers, which operate on alternating current, DC circuit breakers must handle the unique characteristics of direct current. DC circuit breakers are available in various types and ratings to accommodate different DC voltage levels and load requirements. They are commonly used in applications such as solar power systems, battery banks, telecommunications, and automotive electrical systems.

HVDC Circuit Breaker

HVDC (High Voltage Direct Current) circuit breakers are crucial components in high-voltage DC transmission systems. These breakers are designed to interrupt the flow of direct current in HVDC networks, ensuring the safe and reliable operation of power transmission over long distances. HVDC circuit breakers must handle high voltage levels and effectively interrupt the DC current to maintain the stability and integrity of the power grid. They are used in HVDC converter stations and play a vital role in enabling efficient and reliable long-distance power transmission.

Circuit breaker Classification by Installation Location

Indoor Circuit Breakers

Indoor circuit breakers are designed for installation within buildings or enclosed spaces. They provide protection for electrical systems in residential, commercial, and industrial settings. Indoor circuit breakers are typically compact in size and offer features such as easy accessibility for maintenance and protection against environmental factors like dust and moisture. They are commonly used in distribution boards, electrical panels, and control rooms.

Outdoor Circuit Breakers

Outdoor circuit breakers are specifically designed for installation in outdoor environments, where they are exposed to weather conditions and temperature variations. These breakers are housed in weatherproof enclosures that protect them from environmental elements. Outdoor circuit breakers are designed to withstand harsh conditions and provide reliable performance. They are commonly used in substations, power distribution networks, and outdoor industrial applications.

Based on External Design

Dead Tank Circuit Breakers

Dead tank circuit breakers are characterized by their design where the interrupter unit is placed within an earthed metal tank. This design provides excellent insulation and protection against high voltages. Dead tank circuit breakers are commonly used in high-voltage applications, such as power transmission and distribution networks. They offer reliable operation and high breaking capacity.

Live Tank Circuit Breakers

Live tank circuit breakers have a design where the interrupter unit is mounted on an insulating structure and remains live during operation. These breakers are suitable for high-voltage applications and offer advantages such as simplified maintenance, compact size, and ease of installation. Live tank circuit breakers are commonly used in power substations and industrial settings.

According to the Operating Mechanism

Spring-operated Circuit Breaker

Spring-operated circuit breakers utilize mechanical springs to store potential energy, which is released to interrupt the current during a fault. These breakers offer reliable operation, fast response time, and are commonly used in medium and high-voltage applications. They are known for their simplicity, durability, and ability to handle high fault currents.

Pneumatic-operated Circuit Breaker

Pneumatic-operated circuit breakers use compressed air as the operating medium to interrupt the current during a fault. These breakers are suitable for applications where a high-speed response is required, such as in industrial settings or critical systems. They provide reliable performance and can handle high fault currents.

Hydraulic-operated Circuit Breaker

Hydraulic-operated circuit breakers utilize hydraulic pressure to interrupt the current flow. They are known for their high breaking capacity, precise operation, and ability to withstand high fault currents. Hydraulic-operated circuit breakers are commonly used in heavy-duty industrial applications, such as mining equipment and large-scale machinery.

Magnetic-operated Circuit Breaker

Magnetic-operated circuit breakers use an electromagnetic mechanism to trip the breaker when a fault occurs. They offer precise and reliable operation, making them suitable for applications where sensitive equipment or critical systems require protection. Magnetic-operated circuit breakers are commonly used in industries such as aerospace, telecommunications, and data centers.

Magnetic-hydraulic Circuit Breaker

Magnetic-hydraulic circuit breakers combine the principles of both magnetic and hydraulic operation to provide efficient and reliable performance. These breakers offer high breaking capacity, precise trip characteristics, and robust construction. They are commonly used in applications requiring both high fault current handling capabilities and accurate trip coordination.

Special Purpose Circuit Breakers

Motor Protection Circuit Breaker (MPCB)

Motor protection circuit breakers are specifically designed to protect electric motors from overloads, short circuits, and phase failures. They provide comprehensive motor protection by incorporating thermal and magnetic trip units. MPCBs offer features such as adjustable current settings, motor disconnect capabilities, and short-circuit protection. They are commonly used in industrial motor control applications.

Arc Fault Circuit Breakers or AFCIs

Combination Type Arc Fault Circuit Interrupters (AFCIs) are specialized devices that go beyond the capabilities of standard circuit breakers by detecting arcing faults in electrical circuits. Unlike standard breakers that focus on overcurrent protection, AFCIs are designed specifically to identify unintentional arcing conditions that may occur in a circuit. The primary purpose of these devices is to reduce the risks associated with arcing faults by promptly de-energizing the circuit upon detection.

What sets Combination Type AFCIs apart is their ability to detect all three types of arcing: series arcs, parallel arcs, and ground-fault arcs. Series arcs occur when current flow is interrupted along a single conductor, parallel arcs occur when an unintended current path forms between two conductors, and ground-fault arcs occur when current leaks to the ground. By detecting and responding to all three types of arcing, Combination Type AFCIs provide comprehensive protection against a wider range of potential hazards.

When an arcing fault is detected, the Combination Type AFCI acts swiftly to interrupt the circuit, preventing further arcing and mitigating the risk of fire or electrical hazards. These devices are commonly used in residential and commercial settings where electrical fires caused by arcing faults pose a significant threat. By offering enhanced protection against arcing faults, Combination Type AFCIs contribute to improved electrical safety and help minimize the risk of electrical incidents.

SPD Circuit Breaker

A Surge Protective Device (SPD) is a specialized device that combines a highly efficient Transient Voltage Surge Suppressor (TVSS) with two 1-pole circuit breakers. This integrated device brings together the robust characteristics of a secondary circuit breaker surge arrester with the added advantage of lower clamping voltage ratings.

The SPD is designed to provide comprehensive protection against voltage surges or transients caused by lightning strikes, power grid fluctuations, or other electrical disturbances. By integrating the TVSS technology with circuit breakers, this device offers enhanced protection for electrical systems by diverting excessive voltages and limiting them to safe levels.

The TVSS component of the SPD efficiently detects and suppresses transient voltage spikes, preventing them from damaging sensitive electronic equipment. It acts as a first line of defense by absorbing and dissipating the excess energy associated with voltage surges.

In addition to the TVSS, the SPD incorporates two 1-pole circuit breakers. These circuit breakers provide additional safety features by disconnecting the circuit in case of overcurrent or short circuit faults. They contribute to the overall functionality of the SPD by ensuring that the electrical system remains protected from both transient voltage surges and conventional electrical faults.

One of the key advantages of the SPD is its lower clamping voltage ratings. This means that the device can effectively limit the voltage surge to a lower level, thereby minimizing the risk of equipment damage and providing a higher level of protection. The combination of TVSS and circuit breakers in the SPD offers a comprehensive and reliable solution for safeguarding electrical systems against transient voltage surges.

Overall, the integration of a highly effective TVSS with two 1-pole circuit breakers in the Surge Protective Device provides a robust and efficient solution for protecting electrical equipment and systems from the potentially damaging effects of voltage surges. The device offers improved performance, enhanced safety, and reliable operation, making it an essential component in maintaining the integrity and longevity of electrical installations.

Automotive Circuit Breakers

Automotive circuit breakers are designed for use in vehicles to protect the electrical systems from overcurrent. They are compact in size and provide reliable protection against electrical faults. Automotive circuit breakers are commonly used in automotive applications, including cars, trucks, motorcycles, and recreational vehicles.

Type 1 Automatic Reset CB

Type 1 automatic reset circuit breakers are designed to automatically reset and restore power after a temporary overload or fault. These breakers are commonly used in applications where momentary overloads are expected, such as in automotive and marine systems. Type 1 automatic reset circuit breakers offer convenience and ensure continuous operation without manual intervention.

Type 2 Manual Reset CB

Type 2 manual reset circuit breakers require manual intervention to reset and restore power after an overload or fault. They provide additional protection and allow for troubleshooting or maintenance before resetting. Type 2 manual reset circuit breakers are commonly used in applications where a manual reset is preferred for safety reasons or to prevent unintentional re-energization.

Type 3 Push-to-trip CB

Type 3 push-to-trip circuit breakers feature a push-button mechanism that trips the breaker when pressed. They are designed for quick and convenient operation, allowing for easy manual interruption of the circuit. Type 3 push-to-trip circuit breakers are commonly used in applications where rapid response and immediate circuit disconnection are required for safety purposes.