NTC vs PTC Thermistor

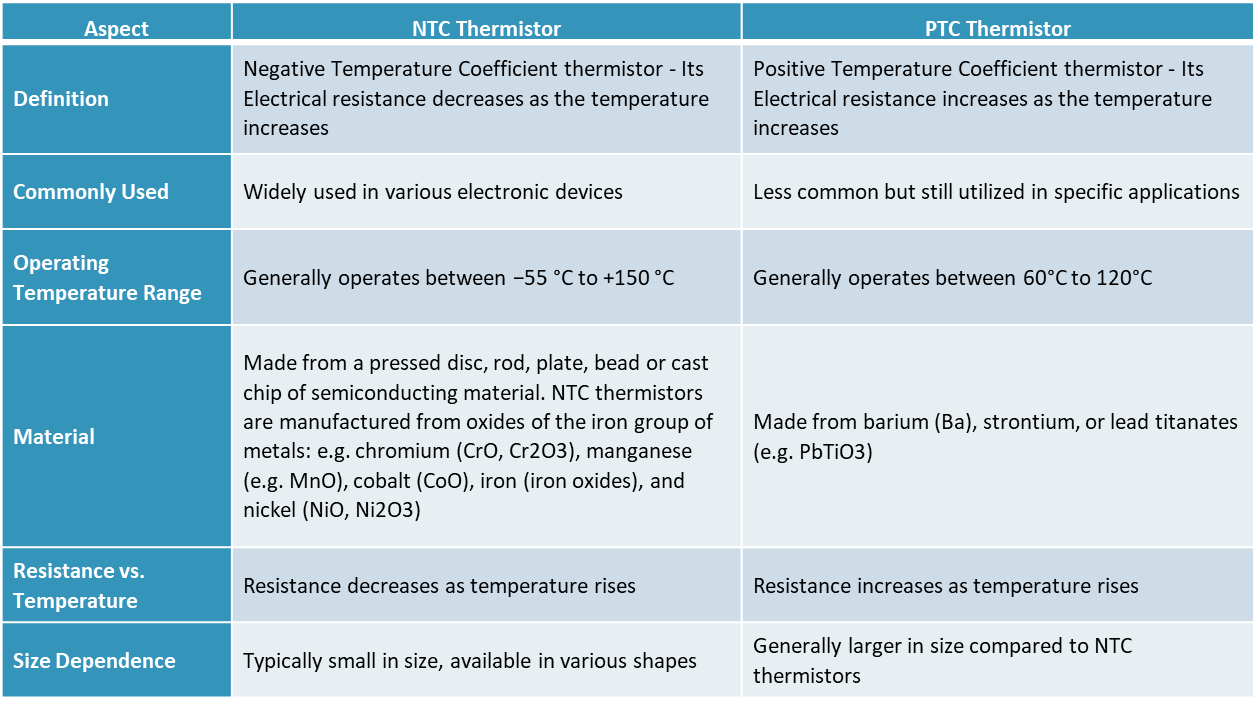

| Property | NTC Thermistor | PTC Thermistor |

|---|---|---|

| Definition | Negative Temperature Coefficient thermistor – Its Electrical resistance decreases as the temperature increases | Positive Temperature Coefficient thermistor – Its Electrical resistance increases as the temperature increases |

| Commonly Used | Widely used in various electronic devices | Less common but still utilized in specific applications |

| Operating Temperature Range | Generally operates between −55 °C to +150 °C | Generally operates between 60°C to 120°C |

| Material | Made from a pressed disc, rod, plate, bead or cast chip of semiconducting material. NTC thermistors are manufactured from oxides of the iron group of metals: e.g. chromium (CrO, Cr2O3), manganese (e.g. MnO), cobalt (CoO), iron (iron oxides), and nickel (NiO, Ni2O3) | Made from barium (Ba), strontium, or lead titanates (e.g. PbTiO3) |

| Resistance vs. Temperature | Resistance decreases as temperature rises | Resistance increases as temperature rises |

| Size Dependence | Typically small in size, available in various shapes | Generally larger in size compared to NTC thermistors |

| Response Time | Quick response time to changes in temperature | Slower response time compared to NTC thermistors |

| Cost | Generally more cost-effective and widely available | Often more expensive due to their specialized applications |

| Excitation Requirement | Require low power to operate effectively | Typically require higher power for proper operation |

| Sensitivity | Generally has high sensitivity to changes in temperature | Generally has moderate sensitivity to temperature fluctuations |

| Linearity | Generally has non-linear response to temperature changes | Has comparativel linear response to temperature changes in some models |